Perch Lake Lumber CO. Layout Rebuild

A long time and a lot of work

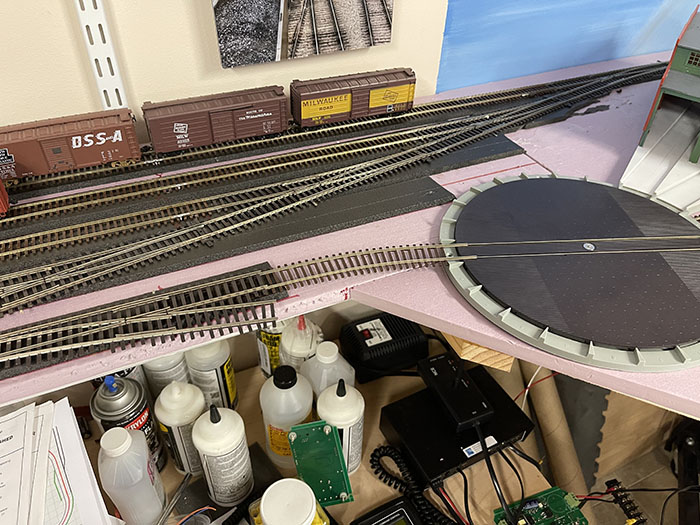

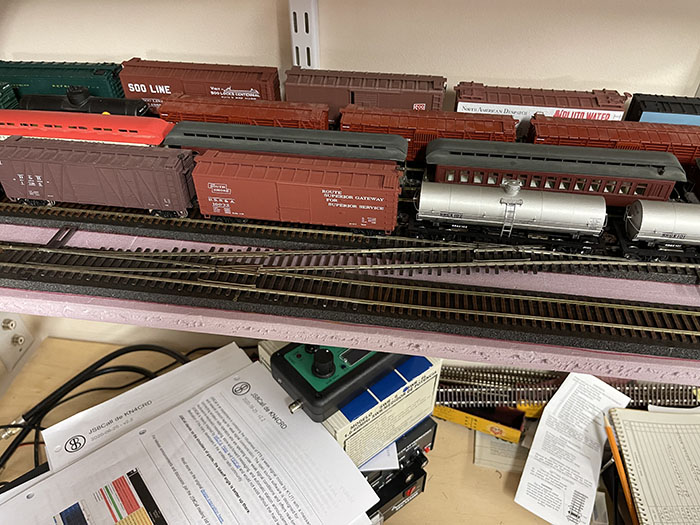

The photos on this page show the last of the hand made turnouts on the layout. I found that the movement between the rails soldered to PC board ties and the next tie being wood had a negative effect on the operation of the layout due to the wide variation of temperature and humidity up in the North Woods.

I therefore replaces 27 turnouts with the new Walthers code83 DCC compatible turnouts. While these turnouts were exact in size and angle for my #5 and #6 turnouts my habit of adding an inch to the length of the turnout rails means each replacement had to be fitted into the main lines with short sections or the mainlines moved in at least one direction to accommodate the new turnouts.

This has been completed along with the installation of tortoise motors under the layout on all turnouts, each having the 8 pins brought back to the control area I have data information as well as frog power where needed.

Each turnout is also equipped with an LED next to the points as an indication to the operators to the position of the turnout. This is something that my club and the SOO Line Historical Society found to be very useful while operation both my North Woods layout as well as my Illinois large layout. While control panels have the indication of the turnouts locomotive engineers may not be able to see or determine the position of the turnout they are approaching.

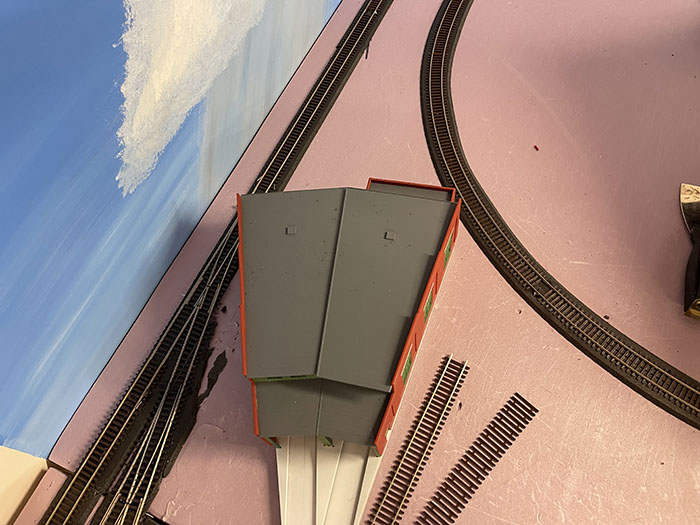

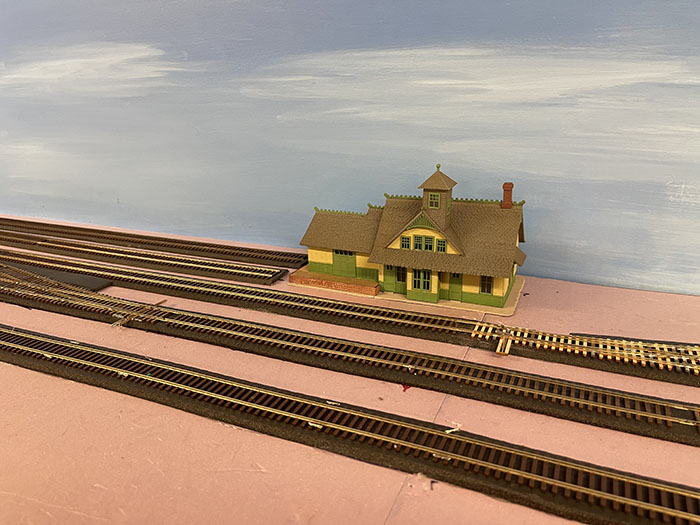

Staging area start by the round house.

Staging area start by the round house.

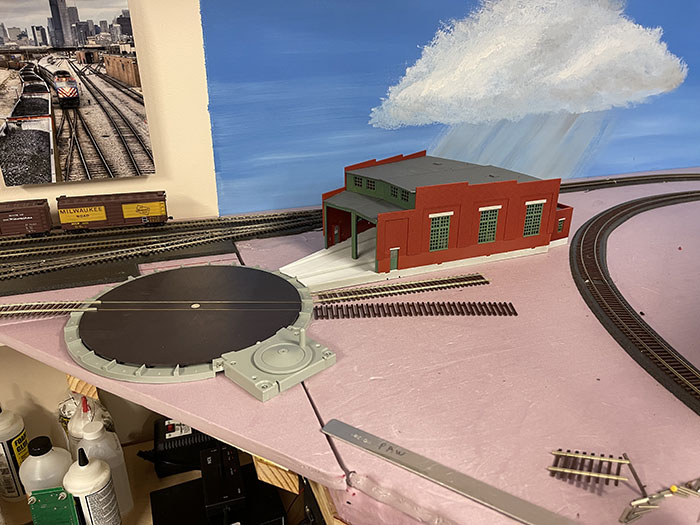

New turntable for the rebuilt Atlas Roundhouse

The last of the homemade turnouts with wood and PC board ites.

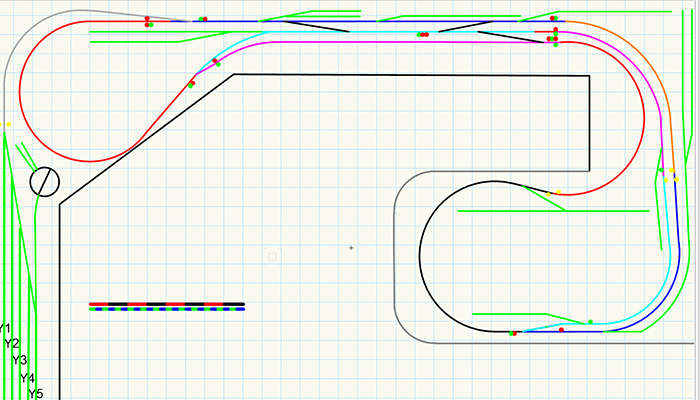

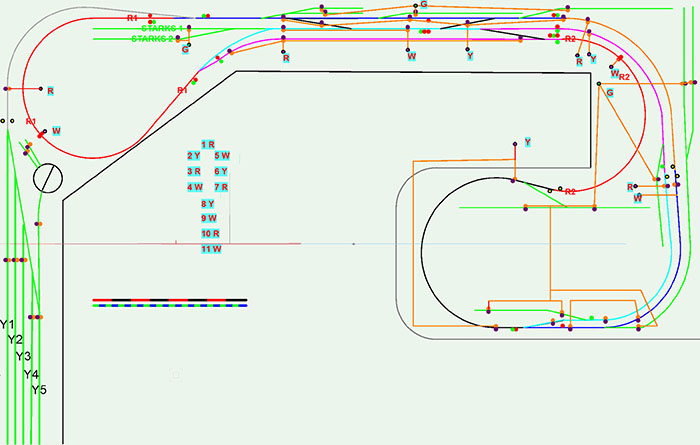

Latest drawing of the PLLC the blocks are marked with the color of the drop wires while the list shows the block numbers and their colors.

If you start at the staging yard lead as block 1 and follow around the layout you will see how the blocks will work. The use of color wires for the drops makes it easy to attach the DB20 detectors to the block feeders. The signals are in red, green, and yellow may show as black dots. The staging lead and the crossovers are electrically operated while all others are ground throws. The ground throws on the main lines report the position of the turnout to the signal system. Sidings in green are powered from their own breaker and shorts will not stop trains on the mains. The mains are divided between the left and right sides of the layout so there is some protection while not shorting the entire layout.

Signals are planned for the layout.

As of 7/10/23 the blocks are in with BD20 units tested while the layout is operational.

Continued in Section 8, is under construction

Return to the start(Click here)

Return to Paul's Workshop (Click here)

Join us in the “Greatest Hobby” as a member of the TLMRC.